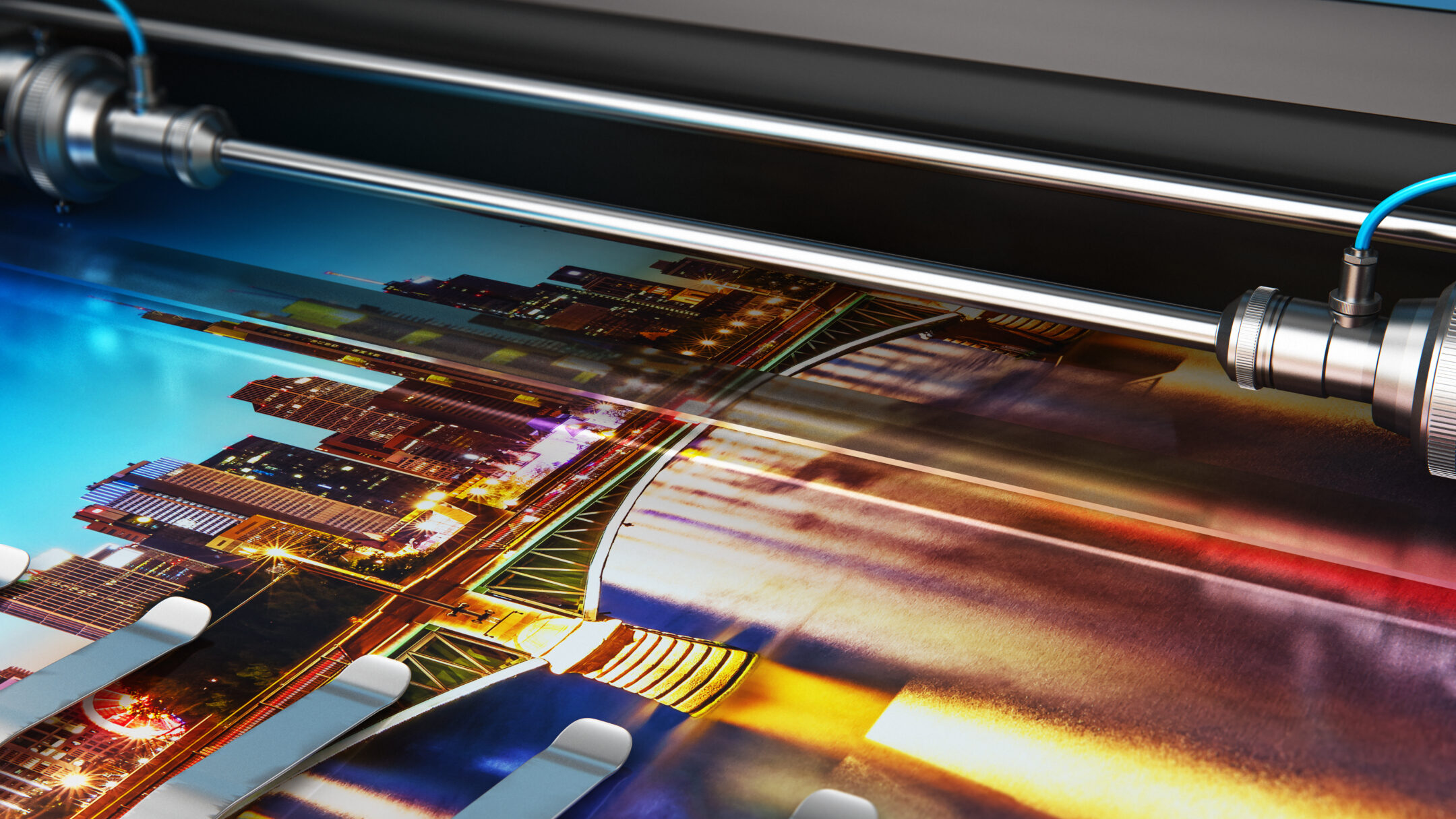

XG Group are experts in graphics and produce industry-leading printed items for event branding, exhibition and display, stadia and commercial interiors.

Based in Brackley, XG Group focus on providing customer service and as a result has long term relationships with many leading agencies and organisations. Clients include the likes of Silverstone Circuits’, British Universities & Colleges Sport (BUCS), Brothers Cider and Mad River agency.

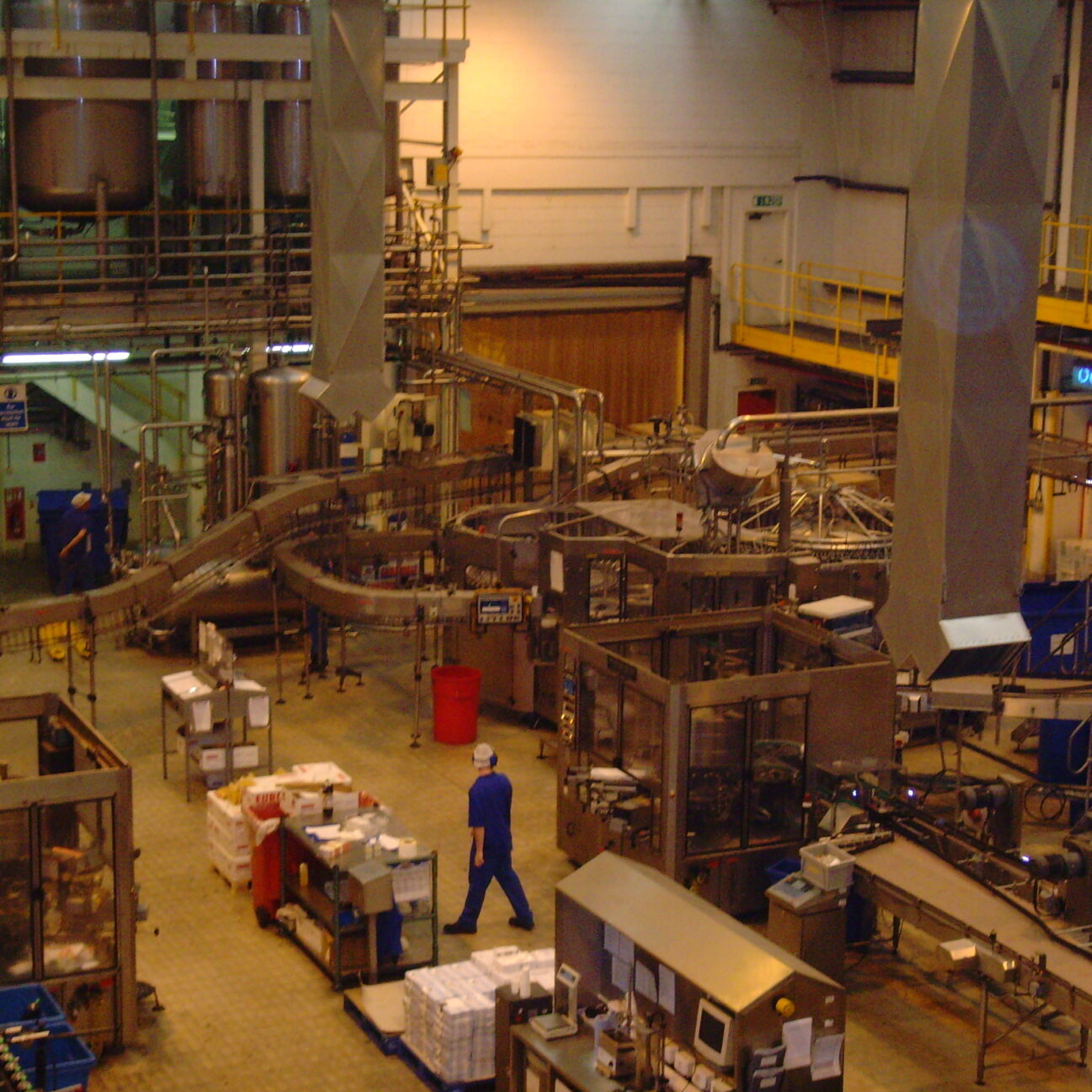

The XG printing workshop, based in Brackley, Northamptonshire is home to industrial printing equipment that produces vast amounts of heat. This meant colleagues were working in uncomfortably hot temperatures throughout the warmer months. XG needed a reliable solution that would effectively cool its large workshop and improve the conditions for workers.

In an attempt to tackle the overheating issue XG Group had previously installed a cheaper, less powerful evaporative cooling system in other similar workshops. Whilst XG could see how effective evaporative cooling was as a technology, the equipment it had was under performing and was failing to meet the cooling requirements. XG knew that it needed a more robust solution for their new area.

XG was, therefore, looking for a high quality evaporative cooling system that would be reliable and provide the level of effectiveness a solution of its kind should.

-

Client

- Location Brackley, Northamptonshire

The Solution

Seeking the right solution, Celsius Design Ltd was contacted and granted the opportunity to provide a better solution to tackle the overheating. As an established EcoCooling installer, Celsius had the ideal solution that would overcome XG’s heat problems.

The installer carried out a survey of the facility to specify the correct number of units for the building, to ensure correct airflow and optimum performance of the system. Celsius installed two EcoCooling evaporative cooling units and two extraction fans. The EcoCooling system fitted was powerful enough to comfortably meet the requirements of the hot workshop and drastically reduce the temperature.

As a blanket cooling solution was required, eight way plenum’s were used to evenly distribute the air across the whole workshop. This would ensure everyone within the space was kept cool.

The installation was completed during normal working hours, working around the personnel and the printing operations. This meant there was no impact on the productivity of the workshop.

The Result

Having reliable and effective units that were fitted by an experienced installer was the key to overcoming XG Group’s overheating problem. The EcoCooling solution installed by Celsius effectively cools the workshop even on the hottest days of the year. XG Group is pleased that it pursued an evaporative cooling system as it is can save around 90% on its energy spend compared to a traditional refrigeration system. What’s more, a single EcoCooler, rated at 35kW, can provide carbon savings of up to 10,000kg per year.

The system was installed in 2017 and easily met the challenging conditions of the very hot summer of 2018, making working conditions much more comfortable for employees.

“XG had been let down by their previous evaporative cooling supplier, due to poor equipment quality and bad installation, therefore they approached Celsius. We designed and installed two new systems for their expanding production areas. Both systems have worked brilliantly in controlling summertime temperatures, especially on the mezzanine floor, which had been unusable previously.”

Jim Jackson

Managing Director, Celsius Design Ltd